Wind Turbine Brake System

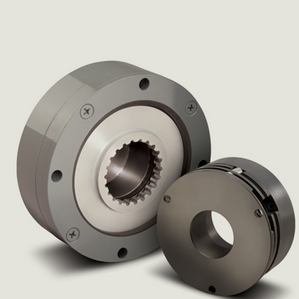

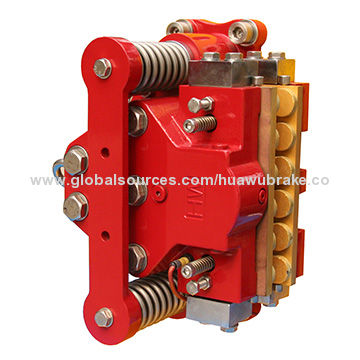

Wind turbine brake system. The first group of brakes is in a normally closed condition and the second. Limiting the turbine power during strong wind conditions but also braking the. In many cases a major parameter regarding brake selection is choosing a friction-liner area of sufficient size to ensure adequate heat dissipation.

The components of a wind turbine are designed so. There are two major different types of wind turbine brakes. Ensures that it automatically stops when it detects that one of its critical components does not work properly.

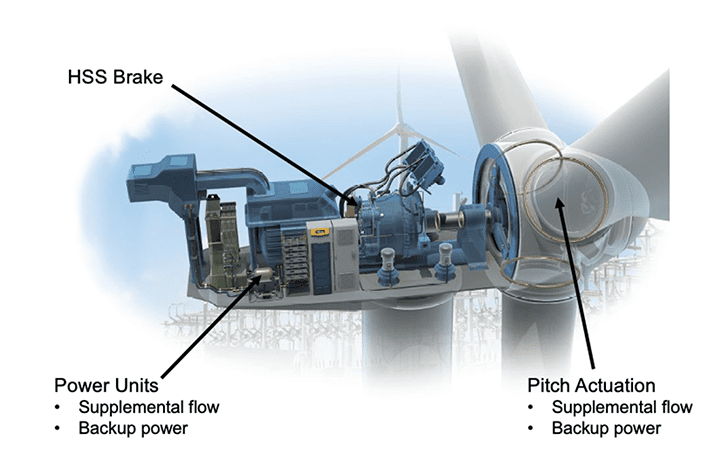

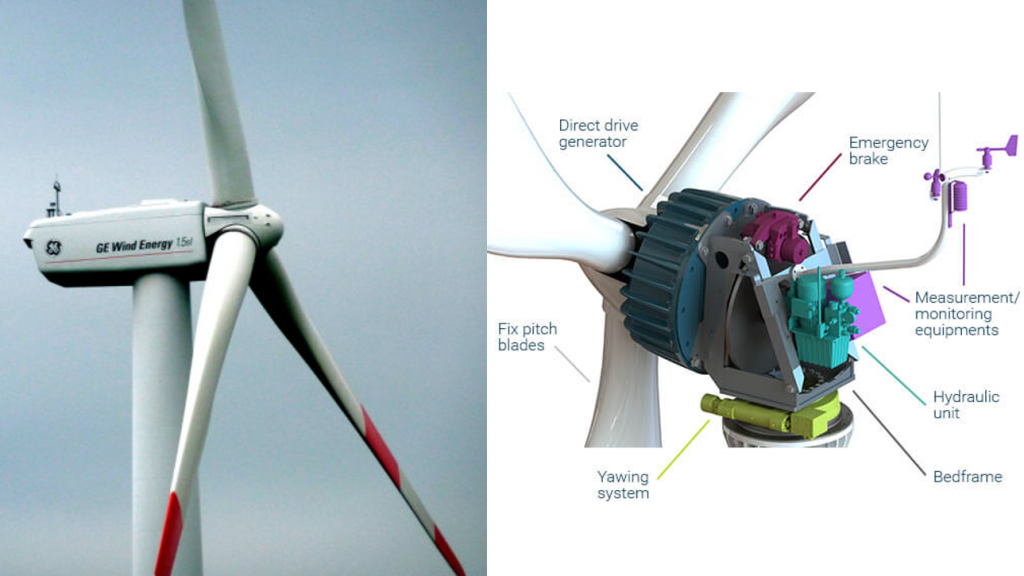

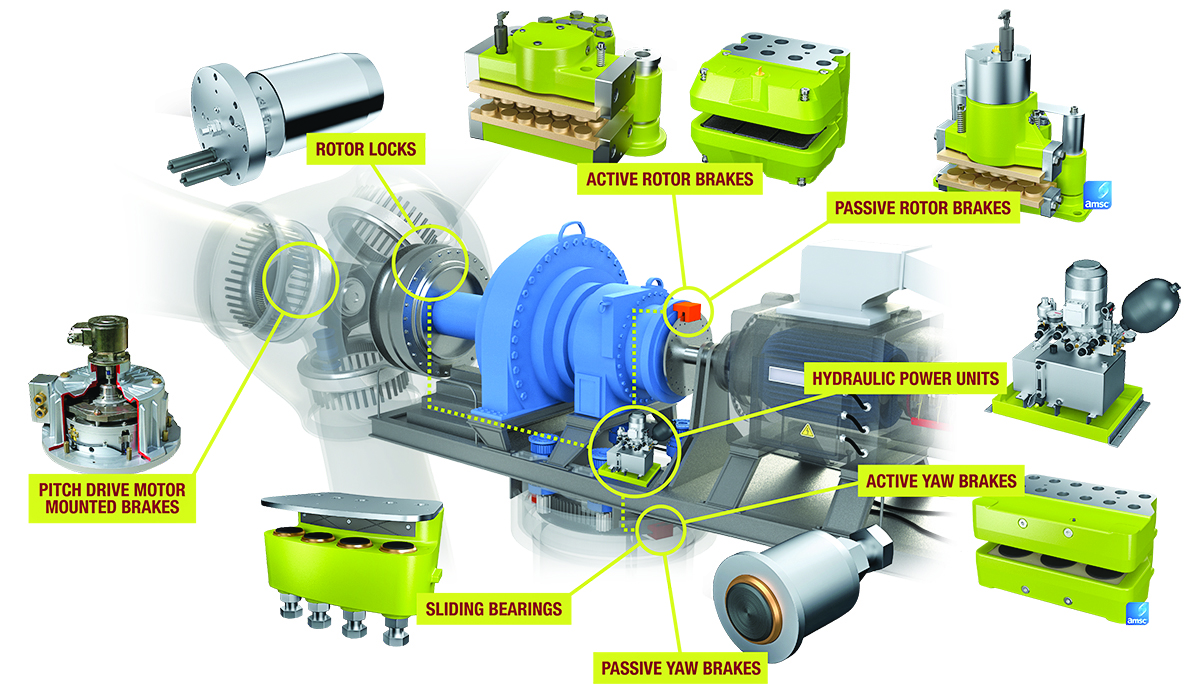

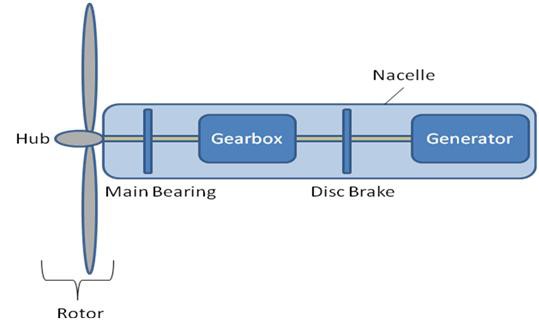

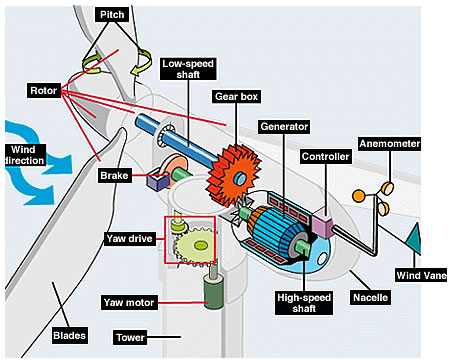

The specific feature of the braking system is the ability of its integration into the wind turbine construction without significant changes. Figure 1 shows the brake systems used in a wind turbine. It helps position the nacelle in the direction of the wind.

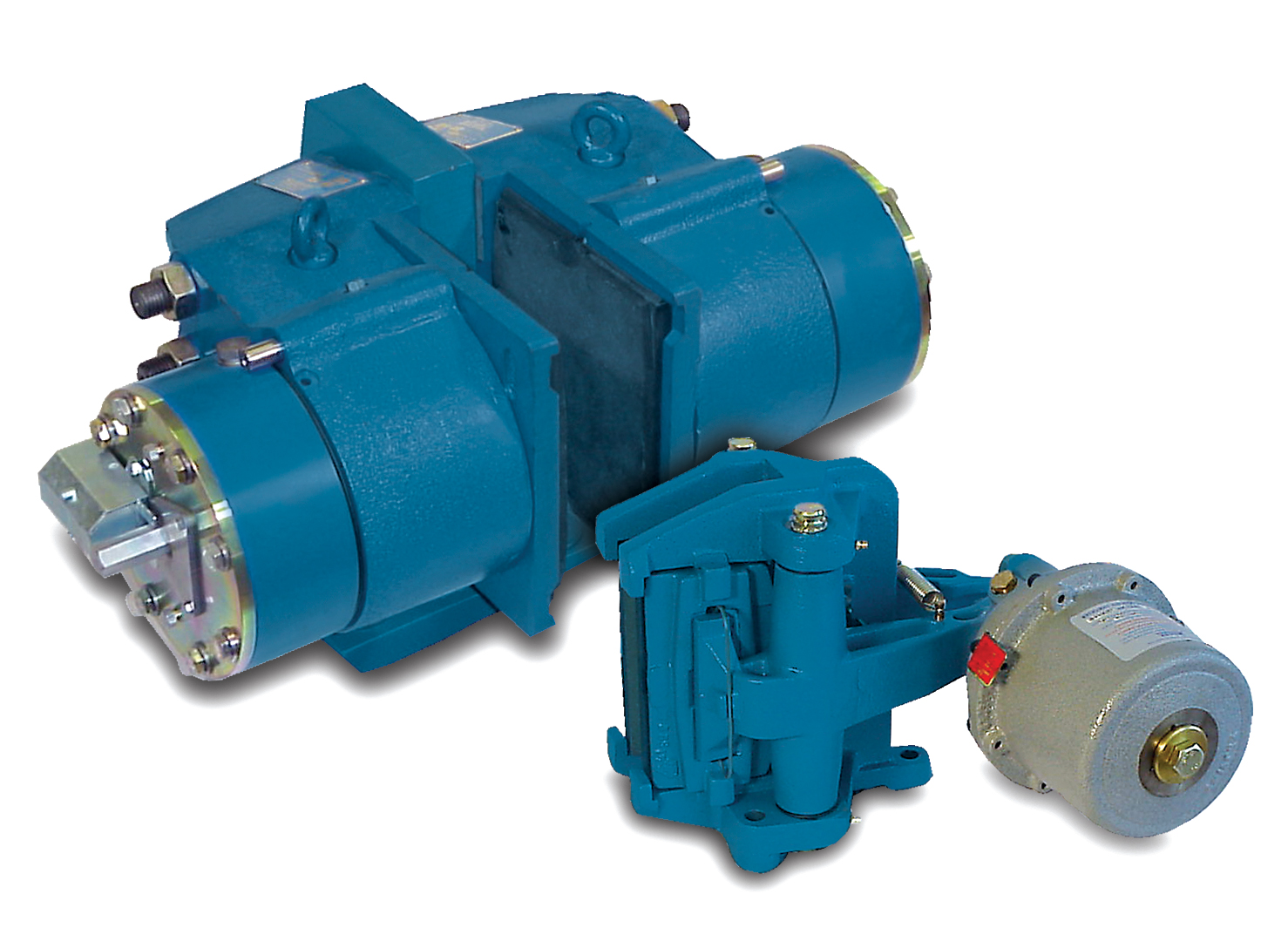

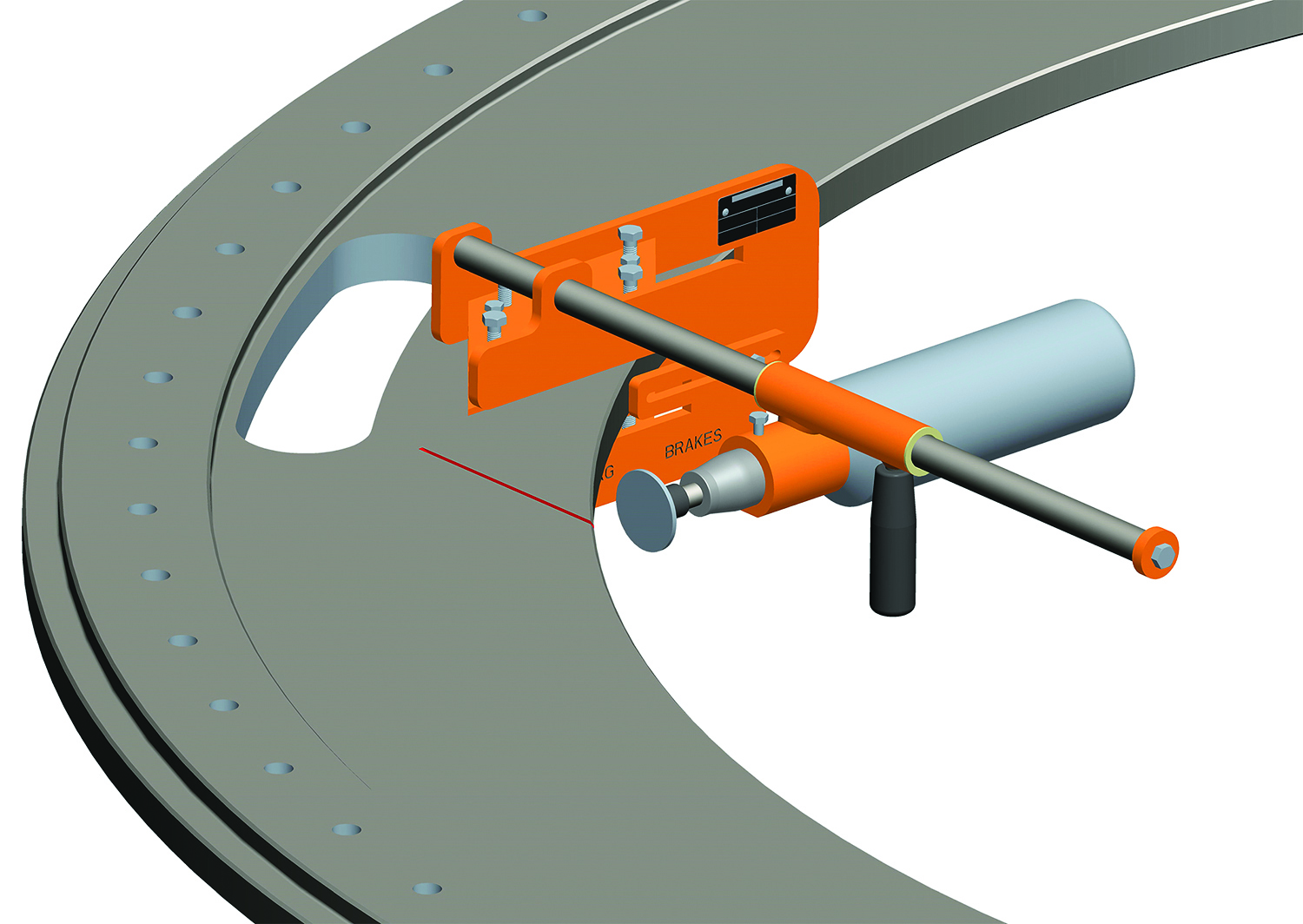

A minimum of four Model BSAB 90 or BSAB 120 hydraulically applied caliper brakes are typically utilized on wind turbine yaw braking systems. The wind turbine brake is classified with the component. Nevertheless braking on the high-speed shaft has been used on many turbines up to 750 kW.

Addition to a rotor brake the brake system of a wind turbine includes a rotor lock that prevents the rotation of a stopped rotor and a yaw brake that controls the yawing of the nacelle of the wind power generator. For more information on the body and inner workings of wind turbines check out this link or for more background on windmills see our page here. The system includes one or more motors 411-416 for driving a part of the wind turbine a first group of brakes 421 423 425 for braking the part of the wind turbine and a second group of brakes 422 424 426 for braking the part of the wind turbine.

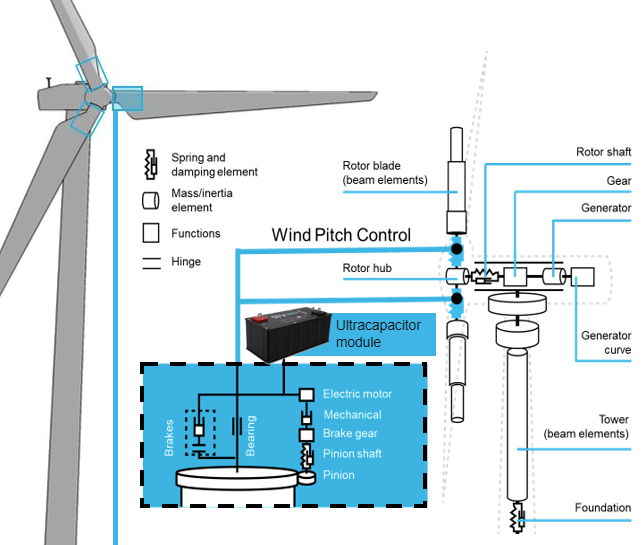

The yaw brake system is an essential component of the wind turbine generator. Blade pitch control is a feature of nearly all large modern horizontal-axis wind turbines. The brake-pad area must be sufficient to control the temperature rise.

The increased ratios of wind-turbine gearboxes produce a large reduction in output torque. Wind-turbine brakes are critical for managing risk and protecting assets in the case of high wind speeds.

Ensures that it automatically stops when it detects that one of its critical components does not work properly.

The wind turbine brake is classified with the component. Wind Turbine Safety - Motiva. You can use a cable disc brake if you wa. For more information on the body and inner workings of wind turbines check out this link or for more background on windmills see our page here. The braking system should be an integral part built into every wind turbine. The first group of brakes is in a normally closed condition and the second. Ensures that it automatically stops when it detects that one of its critical components does not work properly. Theres a lot of kinetic energy generated by the wind turbines and to disperse it properly you have to turn that kinetic energy into heat energy. Figure 1 shows the brake systems used in a wind turbine.

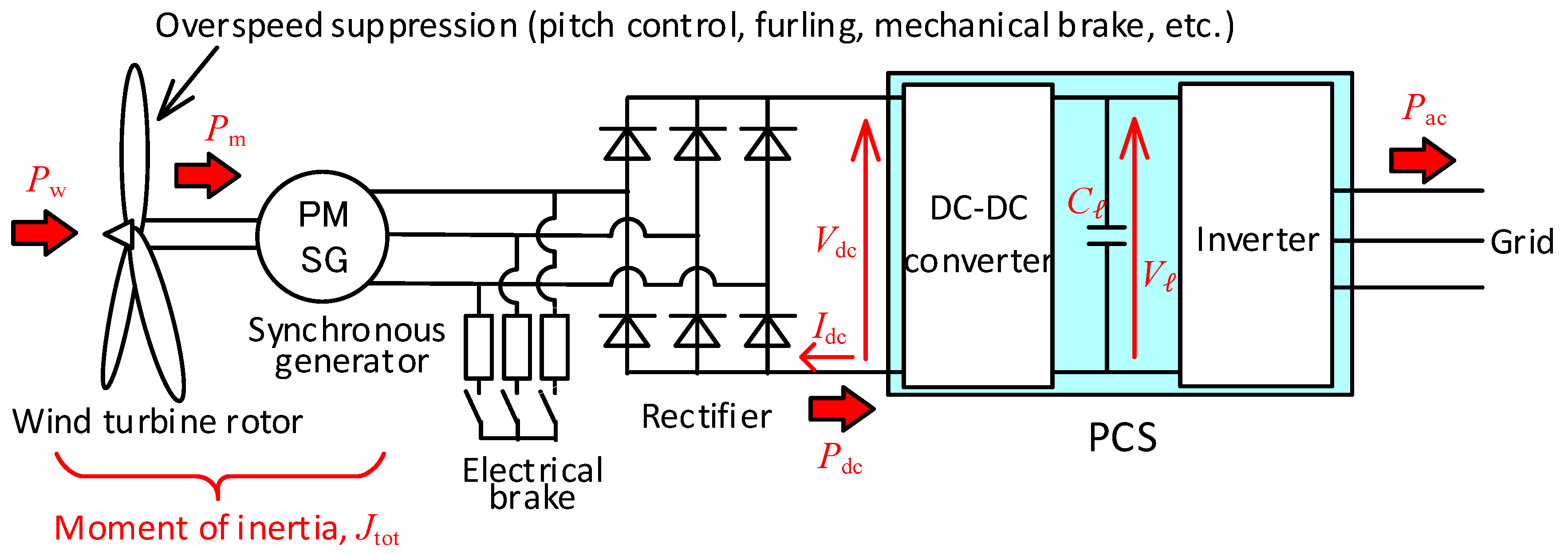

Some wind turbines are fitted with mechanical brakes or aerodynamic braking systems that limit the speed of rotation whilst others require an external electric brake formed by electrical resistors that are connected at the wind turbine output in order to control. It helps position the nacelle in the direction of the wind. Nevertheless braking on the high-speed shaft has been used on many turbines up to 750 kW. A wind turbine yaw brake system can drastically improve maintenance and protect costs. Brakes are key at several locations on a wind turbine. Limiting the turbine power during strong wind conditions but also braking the. Blade pitch control is a feature of nearly all large modern horizontal-axis wind turbines.

Post a Comment for "Wind Turbine Brake System"